Powder coating

HLT completely finishes your products with a coating (in the right RAL colour) in our own paint booth. By coating in-house, we respond even better and faster to your wishes, and we guarantee a short delivery time eliminating additional transport costs.

Powder coating in our own coating line

HLT completely finishes your products with a coating (in the right RAL colour) in our own paint booth. By coating in-house, we respond even better and faster to your wishes, and we guarantee a short delivery time eliminating additional transport costs.

- coating in 1 or 2 layers

- electrostatic spraying

- the part needs to fit inside a box with a maximum of 4.30 m x 2.35 m x 1.20 meters

Powder coating in 8 steps

Pickling and degreasing

Rinse

Rinse with demineralized water

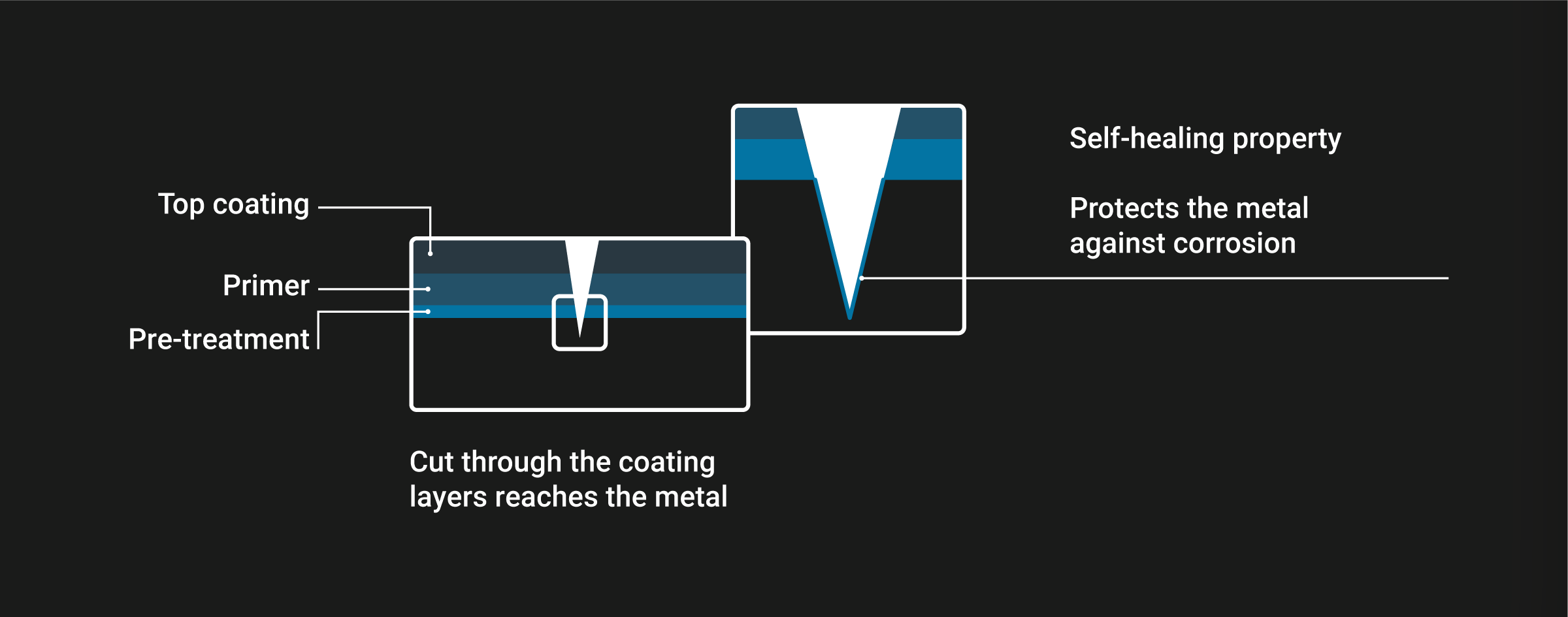

Passivation with nanotechnology

✓ extremely good adhesion of the coating to the metal surface

✓no undermining of the coating in the event of damage

✓ corrosion protection

✓ self-healing property

Remove salt residues

Drying

Electrostatic powder coatings

Muffling in a muffle furnace

Corrosion classes

Corrosion classes C1 t.e.m. C5-M are possible using to a combination of different raw materials and a 1 or 2-layer paint system.

Less transport =

less damage risk

Because HLT can powder coat all parts itself, no additional transport is required. This saves in transport costs. At the same time minimizes the risk of transport damage. This way you get the parts faster and in perfect condition.

Markets

- Architecture

- Indoor / outdoor furniture

- Indoor / outdoor lighting

- Automotive

- Glass production

- Composite

- Electronics / Telecom

- Household appliances

- Merchandising

- Recreation

- Shop interior

- Transport

- Tools

Powder types

POWDER TYPE: POLYESTER

Application:

– Architectural market

– Industrial market

Qualities:

– Improved UV resistance

– Mechanical resistance

POWDER TYPE: EPOXY POLYESTER

Application:

– Household appliances

Qualities:

– Only inside

– Low price

– Increased chemical resistance

POWDER TYPE: POLYURETHANE

Application:

– Anti-graffiti paint

Qualifies:

– Good UV resistance

– Good chemical resistance

POWDER TYPE: EPOXY

Application:

– Corrosion protection

– Primer

Qualities:

– No UV resistance

– Good chemical and mechanical resistance

Looking for the right RAL colour?

Take into account the difference between the colours on your screen and the actual RAL colours. This is due to the settings and quality of your monitor. Using a RAL-colour chart, you’ll find the right colour.

Opt for consistent quality with HLT

Thanks to its own paint shop, HLT has everything for a total service – including powder coating. Starting with the design all the way to the ready-to-use delivery of your items.

- hardly any VOC emissions (Volatile Organic Compounds)

- thicker layer possible without runners or sagging

- 100% recyclable - without waste

- various special effects possible

- cost efficient: easy to apply - without drying time